Download

When replacing a multi-lined selection of text, the generated dummy text maintains the amount of lines. When replacing a selection.

Arnold russel

Online Support

989240005224 hours online support our customer.replacing a multi-lined selection of text.

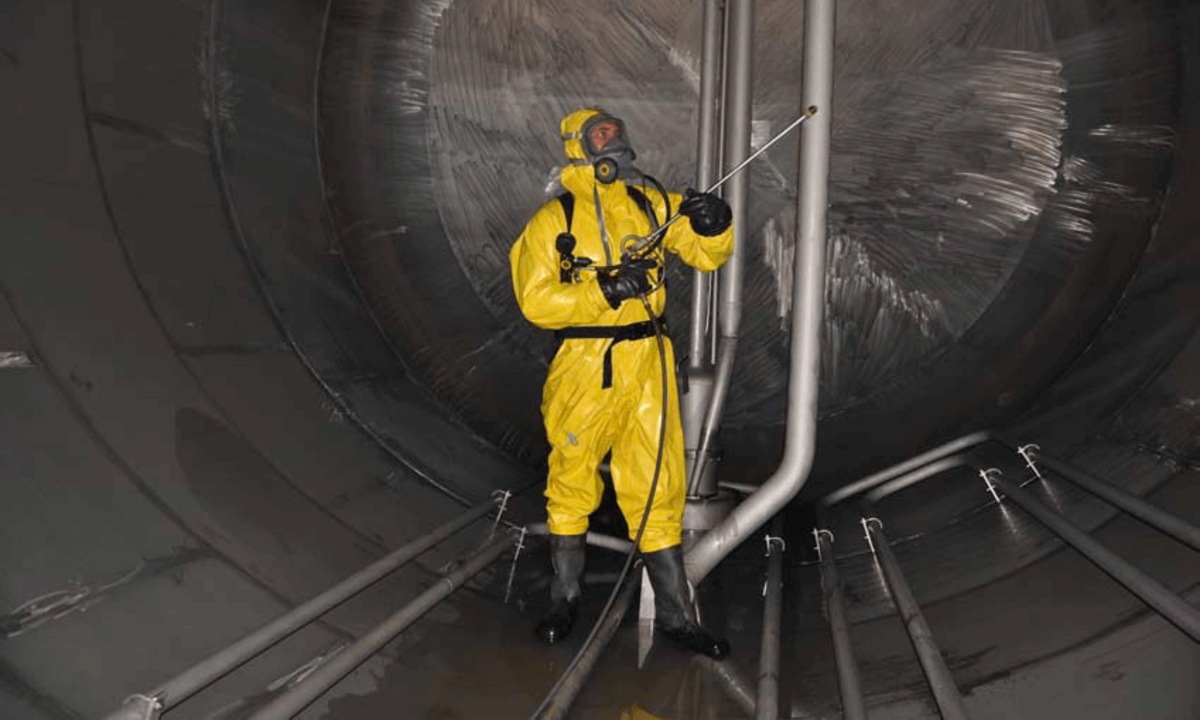

The solution that you have been searching for your carbon sludge tank cleaning issues!

For over a period of time, we at Max cleaning Enviro Services have led the way in structuring integrated microemulsion solutions for carbon sludge tank cleaning operations, crude oil sludge treatment, and oil slop treatment.

Our aim is to develop a real synergy in our approach to effective tank cleaning in Mumbai by combining microemulsion chemistries with the automated systems for tank cleaning.

The cleaning out of the fuel and oil storage tanks, supply vessels and of the tanker trucks to date remains a time-consuming task. On a frequent basis, the cleaning of the tanks results in the production of large quantities of liquid waste that consist of oil, wash fluid, and solids ranging from sand, clay to carbon amongst other particles. Additionally, the actual cleaning part consumes a lot of valuable and expensive time. The fact is the storage tank remains out of service while it is being cleaned, the supply vessel is unavailable and the mud pit cleaning could hold up the procedure for drilling.

However, we have developed the philosophy that carbon sludge tank cleaning and the treatment of the oily waste could and should be done in the most effective way possible, causing least disruption to the operations, and leading to a minimal waste volume. Indeed, our philosophy is that any of the oil that is trapped in the waste either on solids or within the emulsion waste displays a lost value and resource.

Our microemulsions chemistries possess the ability to lower the time that is needed for carbon sludge tank cleaning service in Mumbai from several weeks or days to 1 to 2 days.

Less volume of waste means lower cost

The priciest part of cleaning heavy oil and crude storage tanks is the removal as well as the disposal of the collected sludge. The traditional industrial services and waste management provides charge on the basis of the volume of waste that they get rid of that means they have little reason to lower the amount of sludge prior to the ultimate clean out.

For us, your aim is our aim and by reducing the volume of waste, we help you in:

- Reclaiming formerly unavailable and valuable product,

- Lowering or eradicating sediment that needs to be immediately disposed of,

- Cutting down on the labour hours for cleaning, and

- Significantly reducing tank outage time.

Our procedure for carbon sludge tank cleaning service in Navi Mumbai

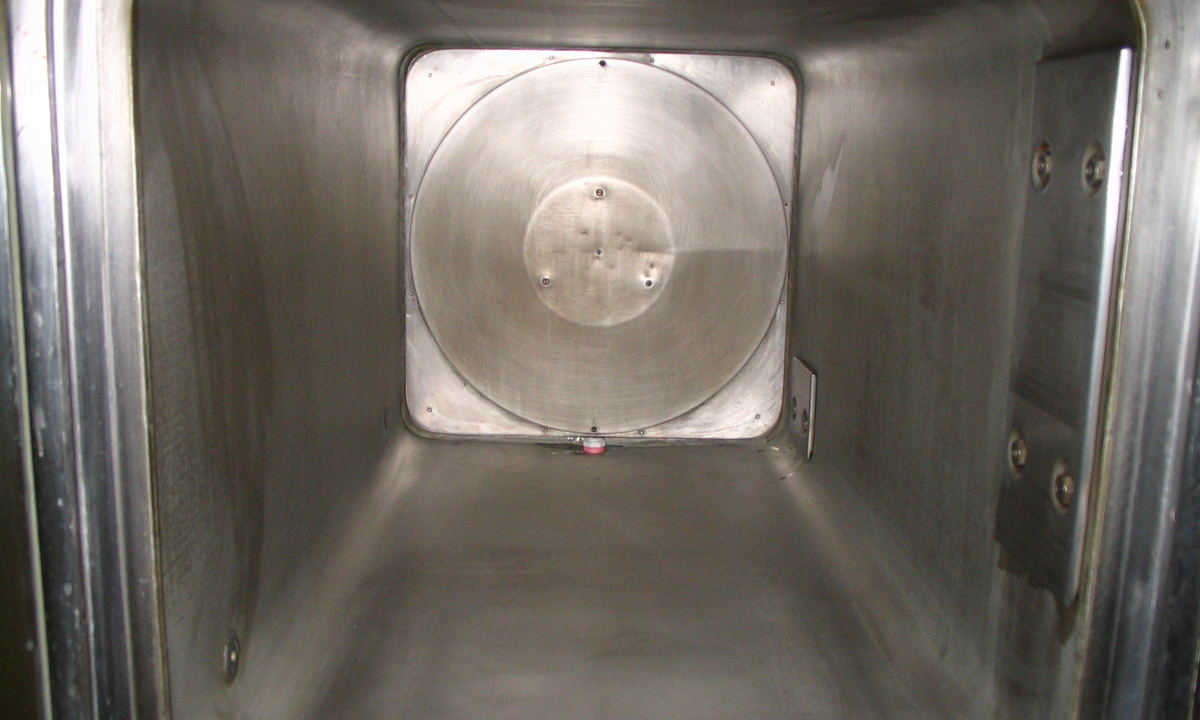

The DS Jet Mixing System

This system gets rid of sludge and regain functional hydrocarbon in your tanks of crude oil storage and the best part is that we do this job without getting your tank out of service at the time of cleaning.

ATC Lance

We know that tank cleaning can be tough and in some cases just impossible when the sludge interferes with the removal of manways. It is our ATC Lance and cold-tap manway process that quickly, effectively, and safely lowers the volume of sludge while recovering the usable hydrocarbons. This eradicates the need to weld on an active tank.

Why choose us?

Our products, process, and manpower have been used to clean out many tanks. Treat hundreds of tonnes of oil emulsion waste, drilling mud slops, and tank bottoms.

Our automated and manual carbon sludge tank cleaning services in Thane are one of the most talked about topics in the industry. Mainly because more than making money out of getting rid of as much waste as we can, we focus on making sure that the tank remains sludge free and highly efficient in its manner of usual functioning.

Leave a Reply